Face Recognition Packaged Software

Bio-IDiom KAOATO

Face Recognition Use Cases in Manufacturing Business

Breadcrumb navigation

Compay Profile

Compay Profile

-

Business type: Manufacturing

-

Number of employees: 300

-

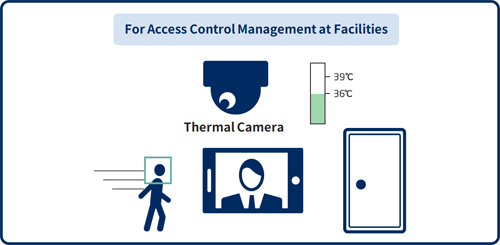

Background of installation: Considering introducing the new access control management system along with construction or relocation of factories.

Installation Background/Issues

Installation Background/Issues

With the construction and relocation of a new factory, we are looking for a new access control system.

- Frequent loading and unloading of parts and products requires hands-free entry and exit.

- In order to prevent foreign substances from being mixed in such as food manufacturing and semiconductor manufacturing, wishing to reduce the number of belongings we have when entering the room.

- Since there are hazardous materials warehouses and dangerous areas, high security is required.

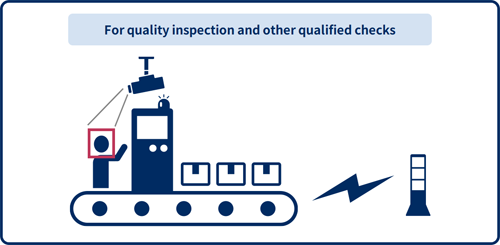

There is a problem with an environment where unqualified people can work on tasks that require qualifications, such as quality inspections.

- There is a problem in the environment where unqualified people can also work on work that requires qualifications such as quality inspection.

- Unqualified employees work instead of busy qualified personnel to meet customer deadlines It is difficult to install a new network in the factory.

Wishing to have something that is highly secure and easy for employees to use.

- Employees have forgotten or lost their IC cards.

- The problem that a qualified employee can accompany someone to a room where am not eligible to enter, or I can enter the room by lending my employee ID card./li>

- Wishing to register one's attendance record at the same time as authentication.

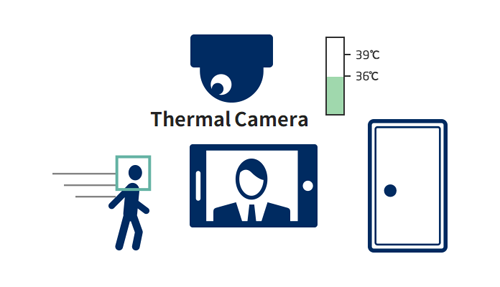

Wishing to improve the efficiency of management as we need to take the temperature and check the temperature of the employee when coming to work.

- Hygienic products are good to prevent infectious diseases.

Solving manufacturing industry's isses with Face Recognition Packaged Software Bio-IDiom KAOATO

Solving manufacturing industry's isses with Face Recognition Packaged Software Bio-IDiom KAOATO

What should be a safe and secure factory?

What needs to be solved to make the factory safe and secure

Occurrence of a period of business suspension due to employee infection

Occurrence of a period of business suspension due to employee infection A large amount of man-hours are required to identify close contacts

A large amount of man-hours are required to identify close contacts

Loss of credibility due to quality inspections by unqualified personnel

Loss of credibility due to quality inspections by unqualified personnel

Complicated attendance management

Complicated attendance management Reduced security due to card lending and borrowing

Reduced security due to card lending and borrowing

Creating a safe and secure environment / Labor saving

|

Access control using IC cards. Staff measures surface temperature in person → Entry/exit and temperature inspection by contact and in person  |

|

Risk of IC card loss, duplication, contact, and droplet infection

|

|

Access control by face recognition

|

|

Prevents unauthorized entry and non-contact door opening

|

Quality Control Enhancement/Inspection Evidence

|

Person in charge is always present at the work location to check if qualified personnel are working → Evidence is personalized  |

|

Man-hours are required to check for qualified personnel. It is necessary to remember the faces and names of all qualified personnel when checking

|

|

Check for qualified personnel by performing facial recognition before and after work

|

|

Facial recognition logs are used as evidence to provide accurate data

|

Work Style Reform/Promote Efficiencyfg

|

AEach employee clocks in with a card, vein authentication, or manual input → Clocking in while touching something  |

|

On cold days, many people cannot correctly authenticate their veins, and there is a risk of false declaration

|

|

Accurate clock-in and clock-out time management by performing face recognition at the entrance door

|

|

Use face recognition to manage accurate employee clock-in and clock-in times

|

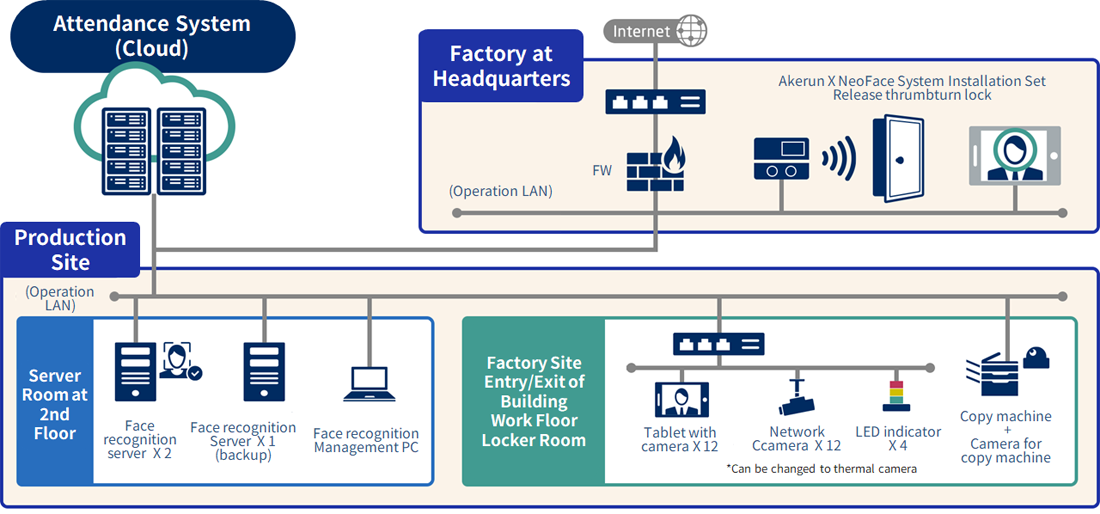

Face Recognition Packaged Software Bio-IDiom KAOATO Installation Summary for Manufacturing Industry

Two face recognition devices installed at entrances and exits (entrance side/exit side)

Face recognition + body surface temperature measurement for entry, face recognition only for exit.

Registers attendance and overtime applications based on face recognition information

The earliest authentication time in a day is linked to the attendance management system, with the latest authentication time as clocking in and clocking out.

Built-in facial recognition function in the inspection terminal

Only the person himself/herself can log in to the inspection system, thus creating a system in which only qualified personnel can work.Face Recognition Package Software Bio-IDiom KAOATO System Configuration Example

Face recognition is used to unify entry and exit of the entire factory. Hands-free” realizes a safe, secure, and easy-to-work-in environment.

1. Access Control

- Unlocking the electronic lock on the entrance door

The result of matching the face recognition data by KAOATO is linked to the electronic lock, and the lock is opened when authentication is OK. By automatically adding images that have been approved for authentication, the certification score will be improved from the next time onwards. - LED indication

The authentication result is displayed on the LED indicator light.

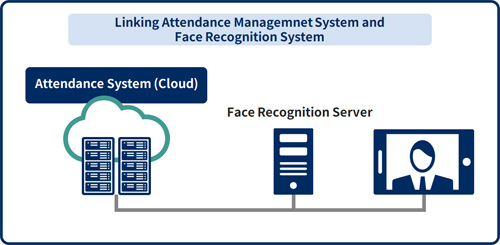

2. Attendance management system linkage

- Linking attendance logs to attendance systems

When you authenticate with a tablet installed at the exit of the changing room, you enter your attendance/departure, and the log (CSV file) of the authentication result output at that time is collected on the server in a daily batch process and provided to the attendance management system. - Measure the surface temperature of employees and register the results in the system.

3. Application for overtime

- Linking attendance logs to attendance systems

Input the start and end of overtime work on a tablet at the site, and the log (CSV file) of the authentication result output at that time is collected on the server in a daily batch process and provided to the attendance management system.

4. MFP Linkage

- Linking KAOATO authentication results to MFPs

Match the face recognition data from the IP camera attached to the MFP with KAOATO, and link the results to the MFP.

5. Monitoring

- Accumulation of data from surveillance cameras

Image data from surveillance cameras is stored on the server.

6. Incorporating face recognition into the inspection terminal

- Incorporating a personal function using face recognition into the inspection terminal

Since only the person himself can log in to the inspection system, we have built a system that only qualified personnel can work.

Face Recognition Packaged Software BIo-IDiom KAOATO Installation Benefits

Improve Security

- Employees can no longer accompany them, and security strength has been improved. Enhancement of quality control and submission of evidence.

Strengthen Quality Control/ Submit Evidence

- Perform face recognition before and after work to check qualified personnel to ensure identity verification and submission of confirmation of work execution.

Enhance Convinience

- By automatically registering attendance and surface temperature check results at the time of entry, convenience is improved for both the registration side and the management side.

Improve Hygiene

- Authentication, surface temperature measurement, attendance registration, and door unlocking without contact with the device.

- Body surface temperature measurement result data can be recorded in attendance management, making it easy for managers to check.

You can read more about Bio-IDiom KAOATO, the face recognition packaged software, from the overview to what it can do, and the fields of application of face recognition here.

Here is a detailed explanation of why face recognition is chosen for access control, and why Bio-IDiom KAOATO is chosen among them.